Reducing fuel costs with smarter tail assignment

Fuel is one of the biggest and most unpredictable expenses for any airline. With prices that can change quickly and growing pressure from environmental regulations, it’s more important than ever to keep an eye on fuel efficiency as a core part of your strategy. When fuel isn’t used efficiently, it cuts into profits and increases your carbon footprint. Things get even trickier when airlines must rely on older, less-efficient aircraft while newer models are grounded—an all-too-common scenario these days.

In this article, we’ll take a closer look at what happens when fuel management isn’t as efficient as it could be—especially when fleets are disrupted. We’ll also show you how an automated, algorithm-driven solution like Jeppesen Tail Assignment can help reduce fuel use and lower emissions so you can make data-driven decisions about which aircraft goes where.

The financial and environmental impact of fuel costs

Fuel expenses account for approximately 20–30% of an airline’s total operating costs, making even marginal improvements in fuel efficiency highly consequential for financial performance. Industry analyses indicate that implementing intelligent fuel management strategies, such as optimized tail assignment, can deliver fuel savings of 2–5% annually, leading to a potential cost reduction of millions of dollars for mid-sized to large carriers.

A 1% improvement in fuel efficiency for a fleet operating 100,000 annual flights can translate to savings of more than $4 million, depending on prevailing fuel prices. These reductions flow directly to the bottom line, enhancing operating margins and increasing overall financial resilience. Furthermore, strategic fuel management is critical for meeting environmental stewardship goals and increasing compliance with tightening regulatory requirements. By prioritizing fuel optimization, airlines can simultaneously achieve sustainability targets, protect profitability, and demonstrate a proactive response to evolving industry standards.

The direct cost of inefficiency

Tail assignment has a material influence on fuel consumption across a network. For instance, operating a less fuel-efficient aircraft on a transcontinental route can increase trip fuel burn by as much as 500–800 kg per flight compared to assigning a next-generation airframe. At scale, these incremental inefficiencies result in substantial financial loss—upward of 1,000 metric tons of excess fuel annually for a fleet of just 20–30 aircraft, equating to well over $750,000 in added direct costs per year.

During operational disruptions impacting next-generation equipment, such as when Airbus A320neo aircraft are grounded due to maintenance actions, the financial penalty escalates. Airlines relying on legacy replacements, for example an airline operating A320ceos in place of grounded A320neos, will typically see fuel burn increase by 15–20% per flight on comparable sectors. This drives both a sharp rise in fuel expenditure and a corresponding increase in carbon emissions for the same volume of operations.

Environmental responsibility and regulatory pressures

Elevated fuel burn has a direct correlation with increased carbon emissions. Every metric ton of jet fuel burned produces approximately 3.16 metric tons of CO2. Data from airlines implementing advanced tail assignment optimization—such as Jeppesen Tail Assignment—demonstrates the potential for CO2 emission reductions of 10,000 metric tons or more annually for medium-sized fleets. This not only aids compliance with programs like the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), but also decreases the financial exposure to emissions offset programs that can average around $2–$5 per ton of CO2, reflecting current offset prices in aviation compliance markets. Airlines with proactive, technology-enabled optimization have reported up to 5% lower overall emissions, enhancing their sustainability profiles and securing a competitive advance in regulatory, investor, and passenger perceptions.

Manual vs automated approaches to reducing fuel costs

Operations controllers are juggling a lot, and fuel efficiency is only one piece of a large, complicated puzzle that also includes things like maintenance schedules, crew assignments, and airport rules. Without automation it can be difficult to determine the most fuel-efficient aircraft for every flight across the whole schedule. Oftentimes, planners rely on general rules of thumb instead of data, which means fuel savings can slip through the cracks.

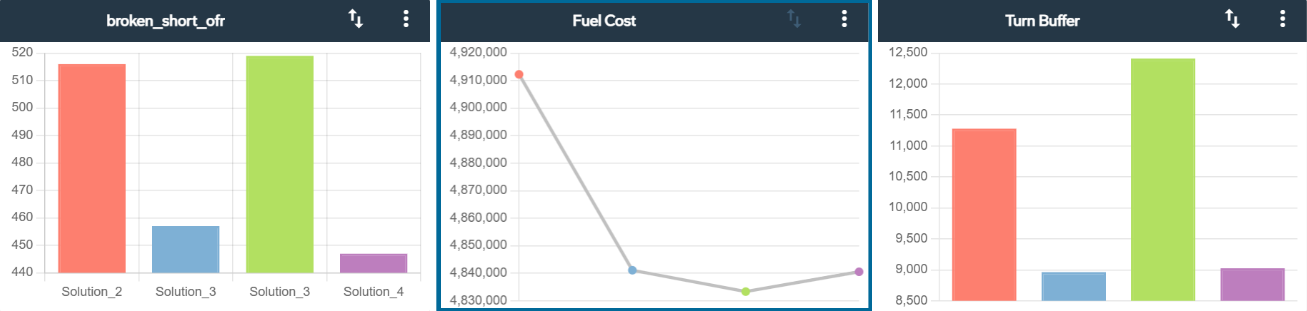

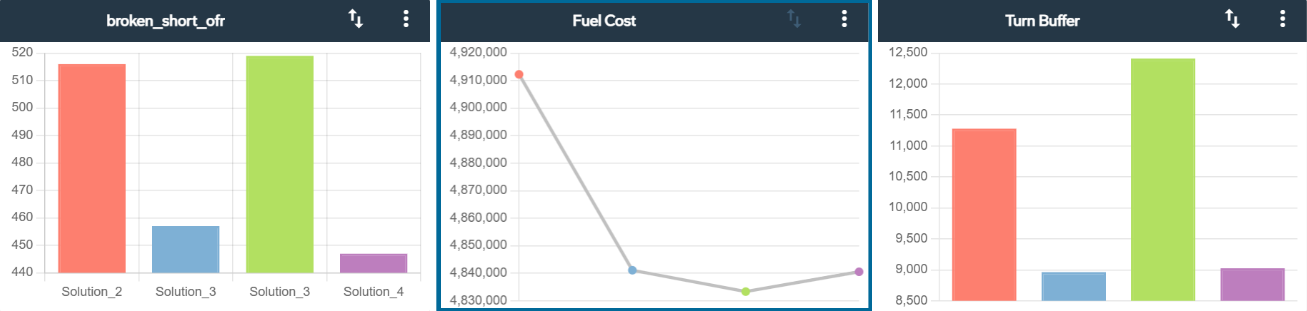

Jeppesen Tail Assignment takes the guesswork out of fuel efficiency by making it a central part of how aircraft are assigned. With comprehensive data models and advanced optimization algorithms, Tail Assignment transforms fuel management into a measurable and automated process, consistently delivering tangible operational advantages.

How Jeppesen aids reducing fuel costs and emissions

- Performance-based assignment: Tail Assignment maintains a detailed performance profile for each airframe in the fleet, including quantifiable metrics such as fuel burn rates. In extensive operational trials, airlines implementing Tail Assignment have demonstrated fuel consumption reductions of up to 2.5% across their schedules, translating to annual savings exceeding $5 million for mid-size operators. The optimization engine systematically evaluates every aircraft-to-route scenario, ensuring the most fuel-efficient aircraft are deployed on high-consumption sectors, including long-haul operations.

- Cost-based optimization: The system integrates a granular cost model that accounts for real-time fuel prices. By using fuel cost as a central driver of the optimization algorithm, Tail Assignment has enabled carriers to achieve an average 2–4% reduction in fuel expenditures annually, depending on baseline operational complexity and network structure.

- Holistic constraint management: By processing all operational constraints—maintenance schedules, crew pairing, and airport restrictions—in parallel, Tail Assignment uncovers fuel-saving opportunities that are not apparent through conventional planning. Case studies report that this integrated, data-driven approach additionally enables reductions in annual CO₂ emissions of up to 8,000 metric tons for airlines operating medium-sized fleets, supporting both economic and environmental targets.

The measurable benefits of an optimized approach

When you put Tail Assignment to work, airlines finally have a straightforward, measurable way to cut fuel use and bring down operating costs. Moving away from manual planning to automated optimization lets you confidently uncover efficiencies that simply weren’t possible before.

Data-driven decisioning to increase fuel efficiency

- Helps protect profits and the environment.

- Helps find ways to burn less fuel in a dynamic world where fuel prices are ever-changing with strict rules/regulations in place

- Gives airlines an advantage to stay competitive and run a more sustainable operation.

Real-world success: $6.5M in fuel savings

A North American airline saved $125,000 in fuel costs within a single week by implementing Tail Assignment, optimizing assignments to cut fuel consumption by 6.16 kilograms per hour. When scaled annually, this translates to an impressive $6.5 million in savings.

Jeppesen Tail Assignment’s contribution to sustainability and savings

Tail Assignment gives airlines an easy way to make fuel efficiency part of their everyday operations. Instead of guesswork or rules-of-thumb, Jeppesen Tail Assignment automatically analyzes millions of possible assignments to find the smartest, most eco-friendly options. This data-driven approach not only helps bring real, measurable savings on fuel costs but also supports bigger sustainability goals—cutting carbon emissions while keeping your operation efficient and responsible.

→ READ NEXT: Mastering tail assignment: 5 strategies for cost savings and on-time performance

Fuel is one of the biggest and most unpredictable expenses for any airline. With prices that can change quickly and growing pressure from environmental regulations, it’s more important than ever to keep an eye on fuel efficiency as a core part of your strategy. When fuel isn’t used efficiently, it cuts into profits and increases your carbon footprint. Things get even trickier when airlines must rely on older, less-efficient aircraft while newer models are grounded—an all-too-common scenario these days.

In this article, we’ll take a closer look at what happens when fuel management isn’t as efficient as it could be—especially when fleets are disrupted. We’ll also show you how an automated, algorithm-driven solution like Jeppesen Tail Assignment can help reduce fuel use and lower emissions so you can make data-driven decisions about which aircraft goes where.

The financial and environmental impact of fuel costs

Fuel expenses account for approximately 20–30% of an airline’s total operating costs, making even marginal improvements in fuel efficiency highly consequential for financial performance. Industry analyses indicate that implementing intelligent fuel management strategies, such as optimized tail assignment, can deliver fuel savings of 2–5% annually, leading to a potential cost reduction of millions of dollars for mid-sized to large carriers.

A 1% improvement in fuel efficiency for a fleet operating 100,000 annual flights can translate to savings of more than $4 million, depending on prevailing fuel prices. These reductions flow directly to the bottom line, enhancing operating margins and increasing overall financial resilience. Furthermore, strategic fuel management is critical for meeting environmental stewardship goals and increasing compliance with tightening regulatory requirements. By prioritizing fuel optimization, airlines can simultaneously achieve sustainability targets, protect profitability, and demonstrate a proactive response to evolving industry standards.

The direct cost of inefficiency

Tail assignment has a material influence on fuel consumption across a network. For instance, operating a less fuel-efficient aircraft on a transcontinental route can increase trip fuel burn by as much as 500–800 kg per flight compared to assigning a next-generation airframe. At scale, these incremental inefficiencies result in substantial financial loss—upward of 1,000 metric tons of excess fuel annually for a fleet of just 20–30 aircraft, equating to well over $750,000 in added direct costs per year.

During operational disruptions impacting next-generation equipment, such as when Airbus A320neo aircraft are grounded due to maintenance actions, the financial penalty escalates. Airlines relying on legacy replacements, for example an airline operating A320ceos in place of grounded A320neos, will typically see fuel burn increase by 15–20% per flight on comparable sectors. This drives both a sharp rise in fuel expenditure and a corresponding increase in carbon emissions for the same volume of operations.

Environmental responsibility and regulatory pressures

Elevated fuel burn has a direct correlation with increased carbon emissions. Every metric ton of jet fuel burned produces approximately 3.16 metric tons of CO2. Data from airlines implementing advanced tail assignment optimization—such as Jeppesen Tail Assignment—demonstrates the potential for CO2 emission reductions of 10,000 metric tons or more annually for medium-sized fleets. This not only aids compliance with programs like the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), but also decreases the financial exposure to emissions offset programs that can average around $2–$5 per ton of CO2, reflecting current offset prices in aviation compliance markets. Airlines with proactive, technology-enabled optimization have reported up to 5% lower overall emissions, enhancing their sustainability profiles and securing a competitive advance in regulatory, investor, and passenger perceptions.

Manual vs automated approaches to reducing fuel costs

Operations controllers are juggling a lot, and fuel efficiency is only one piece of a large, complicated puzzle that also includes things like maintenance schedules, crew assignments, and airport rules. Without automation it can be difficult to determine the most fuel-efficient aircraft for every flight across the whole schedule. Oftentimes, planners rely on general rules of thumb instead of data, which means fuel savings can slip through the cracks.

Jeppesen Tail Assignment takes the guesswork out of fuel efficiency by making it a central part of how aircraft are assigned. With comprehensive data models and advanced optimization algorithms, Tail Assignment transforms fuel management into a measurable and automated process, consistently delivering tangible operational advantages.

How Jeppesen aids reducing fuel costs and emissions

- Performance-based assignment: Tail Assignment maintains a detailed performance profile for each airframe in the fleet, including quantifiable metrics such as fuel burn rates. In extensive operational trials, airlines implementing Tail Assignment have demonstrated fuel consumption reductions of up to 2.5% across their schedules, translating to annual savings exceeding $5 million for mid-size operators. The optimization engine systematically evaluates every aircraft-to-route scenario, ensuring the most fuel-efficient aircraft are deployed on high-consumption sectors, including long-haul operations.

- Cost-based optimization: The system integrates a granular cost model that accounts for real-time fuel prices. By using fuel cost as a central driver of the optimization algorithm, Tail Assignment has enabled carriers to achieve an average 2–4% reduction in fuel expenditures annually, depending on baseline operational complexity and network structure.

- Holistic constraint management: By processing all operational constraints—maintenance schedules, crew pairing, and airport restrictions—in parallel, Tail Assignment uncovers fuel-saving opportunities that are not apparent through conventional planning. Case studies report that this integrated, data-driven approach additionally enables reductions in annual CO₂ emissions of up to 8,000 metric tons for airlines operating medium-sized fleets, supporting both economic and environmental targets.

The measurable benefits of an optimized approach

When you put Tail Assignment to work, airlines finally have a straightforward, measurable way to cut fuel use and bring down operating costs. Moving away from manual planning to automated optimization lets you confidently uncover efficiencies that simply weren’t possible before.

Data-driven decisioning to increase fuel efficiency

- Helps protect profits and the environment.

- Helps find ways to burn less fuel in a dynamic world where fuel prices are ever-changing with strict rules/regulations in place

- Gives airlines an advantage to stay competitive and run a more sustainable operation.

Real-world success: $6.5M in fuel savings

A North American airline saved $125,000 in fuel costs within a single week by implementing Tail Assignment, optimizing assignments to cut fuel consumption by 6.16 kilograms per hour. When scaled annually, this translates to an impressive $6.5 million in savings.

Jeppesen Tail Assignment’s contribution to sustainability and savings

Tail Assignment gives airlines an easy way to make fuel efficiency part of their everyday operations. Instead of guesswork or rules-of-thumb, Jeppesen Tail Assignment automatically analyzes millions of possible assignments to find the smartest, most eco-friendly options. This data-driven approach not only helps bring real, measurable savings on fuel costs but also supports bigger sustainability goals—cutting carbon emissions while keeping your operation efficient and responsible.

→ READ NEXT: Mastering tail assignment: 5 strategies for cost savings and on-time performance