FRM News Flash – March 2020

In the Wake of COVID-19 Turbulence

The aviation industry at large is facing unprecedented challenges at this moment, with disruptions in the wake of the Covid-19 pandemic. Jeppesen is standing by our Customers through these difficult times and we are determined to do our outmost supporting them to return to normality as soon as practically possible.

Fully acknowledging many of our Customers are currently attending to more pressing matters, we aim to continue the distribution of this FRM News Flash, although with a somewhat lower frequency until further notice.

Vistara Opts for Jeppesen Crew Rostering and BAM

Vistara, India’s finest full-service carrier and a joint venture of Tata group and Singapore Airlines, has purchased the state-of-the-art Jeppesen Crew Rostering and BAM for their crew management process.

“Jeppesen Crew Rostering and BAM were purchased to ensure we consistently and timely produce the best possible rosters for our crew members”, says an official spokesperson at Vistara. “The optimization capability in the product will be used for decision support and in the monthly production, to ensure that we arrive at a balance between our planning aspects – such as robustness, fatigue risk, cost and crew efficiency”, the spokesperson continues.

“We are excited to welcome Vistara to the Jeppesen family of operators and are thrilled to now engage with them during the implementation phase in the months to come”, comments Kedarinath ‘KD’ Shastry, Sales Director, Boeing Global Services.

Please find here more information on JCR and BAM.

Consumer Devices on Par With Actigraphy?

Collecting detailed sleep data from crew is often a part of building evidence for a safety business case but also a neccessity when improving upon fatigue models such as the Boeing Alertness Model. This type of data has traditionally been collected using both manually recorded sleep/wake diaries and so-called ‘actiwatches’ – a medical grade instrument containing accelerometers registering movement. The movement data is later interpreted by software algorithms into likely sleep/wake periods for the person wearing the device. The drawback with this, which has limited the amount of collected data, has been the extensive logistics needed and the very costly devices.

of building evidence for a safety business case but also a neccessity when improving upon fatigue models such as the Boeing Alertness Model. This type of data has traditionally been collected using both manually recorded sleep/wake diaries and so-called ‘actiwatches’ – a medical grade instrument containing accelerometers registering movement. The movement data is later interpreted by software algorithms into likely sleep/wake periods for the person wearing the device. The drawback with this, which has limited the amount of collected data, has been the extensive logistics needed and the very costly devices.

It seems now, not surprisingly, that the fast development and high interest in wearable devices is quickly closing the capability gap between the older more expensive technology of actiwatches and modern low-cost fitness bands used by millions of people. A recent publication comparing the technologies arrived at this conclusion: ‘A consumer-grade wearable device can measure sleep duration just as well as a research actigraph. However, sleep staging would benefit from further refinement before these methods can be reliably used for adolescents.’

With more of these validation studies coming up, which really has been the limiting factor – not the technology itself, it is likely that we can soon capitalize from much larger data sets. We can then improve crew rosters even further when fatigue models are used proactively to influence the sequencing of activities for crew. Happy days indeed. Please find a link to the abstract here. (The full paper is behind a paywall.)

Empower Your Current Crew Solution

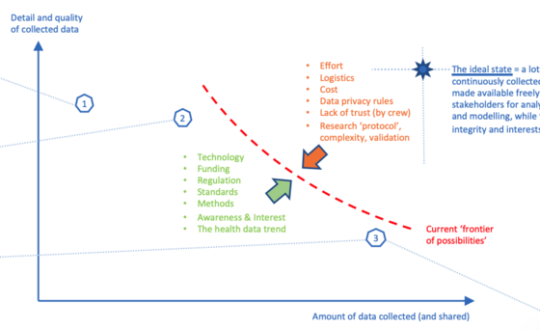

Were you aware that your existing crew management solution can easily be empowered by leading FRM functionality? Jeppesen Concert, using the Boeing Alertness Model (BAM), can quickly be added to whatever system you have right now. It provides detailed analytics, allows you to quantify fatigue risk, capture trends over time per fleet, rank and base, and also identifies your hotspots. Concert allows you to drill into the details of planned and flown rosters, providing you with insights into the roster-driven fatigue risk in your operation.

Why not give Concert a try and benchmark it to whatever tool you use right now? You are welcome to contact us here for setting up a trial.

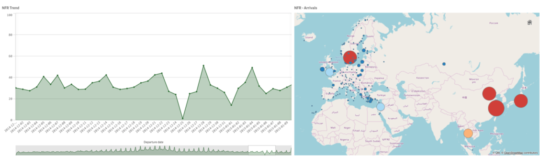

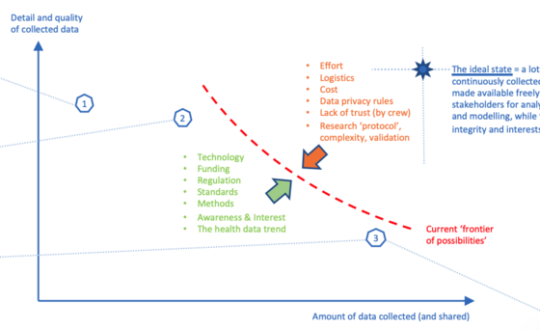

An Improved Approach to Fatigue Data Collection

What should you do when fatigue reporting fail to deliver the needed insights, and traditional fatigue data collection is overly-expensive and cumbersome? We think we have found the answer – and it is a dead simple one. Please find here a poster used last fall at the Shiftwork Conference in Coeur d’Alene, presented by Jeppesen and NLR, describing the problem and a possible way forward.

An effective way of compensating for the low signal-to-noise ratio in crew fatigue data, is by dramatically increasing the measurements by making them much easier for the crew to collect.

An effective way of compensating for the low signal-to-noise ratio in crew fatigue data, is by dramatically increasing the measurements by making them much easier for the crew to collect.

This enablea the FSAG to become more data driven and action insights founded in representative data.

You are most welcome to contact us to discuss how Jeppesen can assist you in getting up and running with a broader, even continuous, fatigue data collection.

jeppesen.com/frm

+46 31 720 81 00

Send us an Email

In the Wake of COVID-19 Turbulence

The aviation industry at large is facing unprecedented challenges at this moment, with disruptions in the wake of the Covid-19 pandemic. Jeppesen is standing by our Customers through these difficult times and we are determined to do our outmost supporting them to return to normality as soon as practically possible.

Fully acknowledging many of our Customers are currently attending to more pressing matters, we aim to continue the distribution of this FRM News Flash, although with a somewhat lower frequency until further notice.

Vistara Opts for Jeppesen Crew Rostering and BAM

Vistara, India’s finest full-service carrier and a joint venture of Tata group and Singapore Airlines, has purchased the state-of-the-art Jeppesen Crew Rostering and BAM for their crew management process.

“Jeppesen Crew Rostering and BAM were purchased to ensure we consistently and timely produce the best possible rosters for our crew members”, says an official spokesperson at Vistara. “The optimization capability in the product will be used for decision support and in the monthly production, to ensure that we arrive at a balance between our planning aspects – such as robustness, fatigue risk, cost and crew efficiency”, the spokesperson continues.

“We are excited to welcome Vistara to the Jeppesen family of operators and are thrilled to now engage with them during the implementation phase in the months to come”, comments Kedarinath ‘KD’ Shastry, Sales Director, Boeing Global Services.

Please find here more information on JCR and BAM.

Consumer Devices on Par With Actigraphy?

Collecting detailed sleep data from crew is often a part of building evidence for a safety business case but also a neccessity when improving upon fatigue models such as the Boeing Alertness Model. This type of data has traditionally been collected using both manually recorded sleep/wake diaries and so-called ‘actiwatches’ – a medical grade instrument containing accelerometers registering movement. The movement data is later interpreted by software algorithms into likely sleep/wake periods for the person wearing the device. The drawback with this, which has limited the amount of collected data, has been the extensive logistics needed and the very costly devices.

of building evidence for a safety business case but also a neccessity when improving upon fatigue models such as the Boeing Alertness Model. This type of data has traditionally been collected using both manually recorded sleep/wake diaries and so-called ‘actiwatches’ – a medical grade instrument containing accelerometers registering movement. The movement data is later interpreted by software algorithms into likely sleep/wake periods for the person wearing the device. The drawback with this, which has limited the amount of collected data, has been the extensive logistics needed and the very costly devices.

It seems now, not surprisingly, that the fast development and high interest in wearable devices is quickly closing the capability gap between the older more expensive technology of actiwatches and modern low-cost fitness bands used by millions of people. A recent publication comparing the technologies arrived at this conclusion: ‘A consumer-grade wearable device can measure sleep duration just as well as a research actigraph. However, sleep staging would benefit from further refinement before these methods can be reliably used for adolescents.’

With more of these validation studies coming up, which really has been the limiting factor – not the technology itself, it is likely that we can soon capitalize from much larger data sets. We can then improve crew rosters even further when fatigue models are used proactively to influence the sequencing of activities for crew. Happy days indeed. Please find a link to the abstract here. (The full paper is behind a paywall.)

Empower Your Current Crew Solution

Were you aware that your existing crew management solution can easily be empowered by leading FRM functionality? Jeppesen Concert, using the Boeing Alertness Model (BAM), can quickly be added to whatever system you have right now. It provides detailed analytics, allows you to quantify fatigue risk, capture trends over time per fleet, rank and base, and also identifies your hotspots. Concert allows you to drill into the details of planned and flown rosters, providing you with insights into the roster-driven fatigue risk in your operation.

Why not give Concert a try and benchmark it to whatever tool you use right now? You are welcome to contact us here for setting up a trial.

An Improved Approach to Fatigue Data Collection

What should you do when fatigue reporting fail to deliver the needed insights, and traditional fatigue data collection is overly-expensive and cumbersome? We think we have found the answer – and it is a dead simple one. Please find here a poster used last fall at the Shiftwork Conference in Coeur d’Alene, presented by Jeppesen and NLR, describing the problem and a possible way forward.

An effective way of compensating for the low signal-to-noise ratio in crew fatigue data, is by dramatically increasing the measurements by making them much easier for the crew to collect.

An effective way of compensating for the low signal-to-noise ratio in crew fatigue data, is by dramatically increasing the measurements by making them much easier for the crew to collect.

This enablea the FSAG to become more data driven and action insights founded in representative data.

You are most welcome to contact us to discuss how Jeppesen can assist you in getting up and running with a broader, even continuous, fatigue data collection.

| jeppesen.com/frm | +46 31 720 81 00 | Send us an Email |